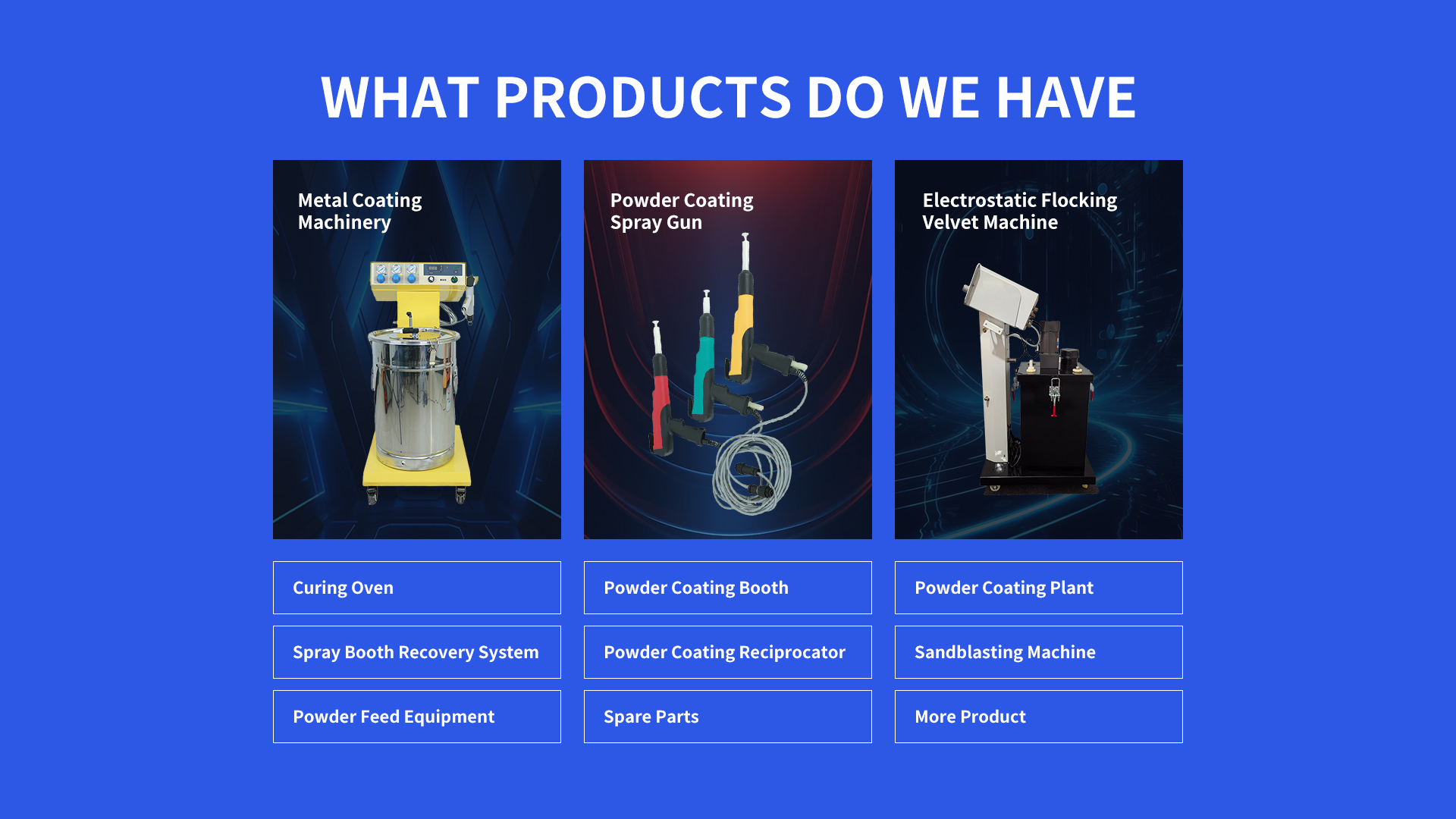

1. Aluminium Powder Coating Spray Machine Components and Design

An Aluminium Powder Coating Spray Machine is engineered to apply durable, corrosion-resistant coatings to aluminium surfaces. Key components include an electrostatic spray gun (corona or tribo-charging), powder hopper, high-voltage generator, control interface, and recovery system. Specialized designs feature anti-static hoses and nozzles to prevent powder buildup. Advanced models integrate automated conveyor belts for high-throughput production of aluminium profiles, sheets, and extrusions.

2. Applications of Aluminium Powder Coating Spray Machines

These machines are vital in industries like architectural aluminium (window frames, façades), automotive (alloy wheels, engine parts), and consumer electronics (laptop casings). They provide UV-resistant, scratch-proof finishes for outdoor signage, marine components, and HVAC systems. Aluminium’s lightweight properties make it ideal for aerospace applications, where precision-coated parts reduce weight without compromising strength.

3. Aluminium Powder Coating Spray Machine Pricing

Manual spray guns start at 1,000forsmallworkshops.Semi−automaticsystemsrangefrom5,000–25,000,suitableformedium−scalealuminiumfabricators.Fullyautomatedlineswithroboticarmsandcuringovensexceed80,000, designed for industrial manufacturers. Costs vary based on throughput (15–200 kg/hour), energy efficiency, and aluminium-specific features like anti-oxidation filters.

4. Best Practices for Operating Aluminium Powder Coating Spray Machines

Surface Prep: Degrease aluminium with alkaline cleaners and apply chromate conversion coatings.

Spray Settings: Use 50–100 kV voltage and 0.8–1.5 bar airflow for optimal adhesion.

Gun Technique: Maintain 10–20 cm distance; apply multiple thin layers to avoid drips.

Curing: Heat aluminium substrates to 180–200°C for 10–15 minutes to ensure crosslinking.

5. How to Select the Right Aluminium Powder Coating Spray Machine

Production Volume: Choose automated lines for mass production of architectural aluminium profiles.

Powder Type: Opt for polyester or hybrid powders for outdoor durability.

Compatibility: Ensure the machine supports pre-treated aluminium surfaces (e.g., anodized or etched).

Certifications: Prioritize CE, ISO 9001, and ATEX compliance for hazardous environments.

6. Safety Protocols for Aluminium Powder Coating Operations

Explosion Prevention: Use grounded equipment (<1 ohm) and Class II Division 1-rated electrical systems.

Respiratory Protection: Equip operators with NIOSH N95 masks to avoid inhaling fine aluminium particles.

Ventilation: Install spark-resistant exhaust systems to mitigate combustible dust risks.

Fire Safety: Store aluminium powder in sealed containers away from ignition sources.

7. Design Efficiency in Aluminium Powder Coating Spray Machines

Modern designs prioritize rapid color-change systems (under 5 minutes) for diverse aluminium products. Energy-efficient curing ovens reduce power consumption by 25%, while IoT-enabled diagnostics monitor coating thickness (±5μm accuracy). Ergonomic spray guns minimize operator fatigue during prolonged use.

8. Key FAQs on Aluminium Powder Coating Spray Machines

Q: Why is surface pretreatment critical for aluminium powder coating?

A: Pretreatment removes oxides and enhances adhesion, preventing coating delamination on aluminium surfaces.

Q: Can these machines coat irregularly shaped aluminium parts?

A: Yes, 6-axis robotic arms ensure uniform coverage on complex geometries like heat sinks or automotive trims.

Q: How to maintain consistent color on aluminium substrates?

A: Use calibrated powder feed rates and ensure curing temperature stability (±3°C tolerance).

Q: Are aluminium powder coatings recyclable?

A: Yes, recovery systems reclaim 95%+ overspray, aligning with circular economy principles.

Q: What distinguishes aluminium-compatible Aluminium Powder Coating Spray Machines?

A: Anti-static components and specialized nozzles prevent powder clogging during high-volume aluminium processing.

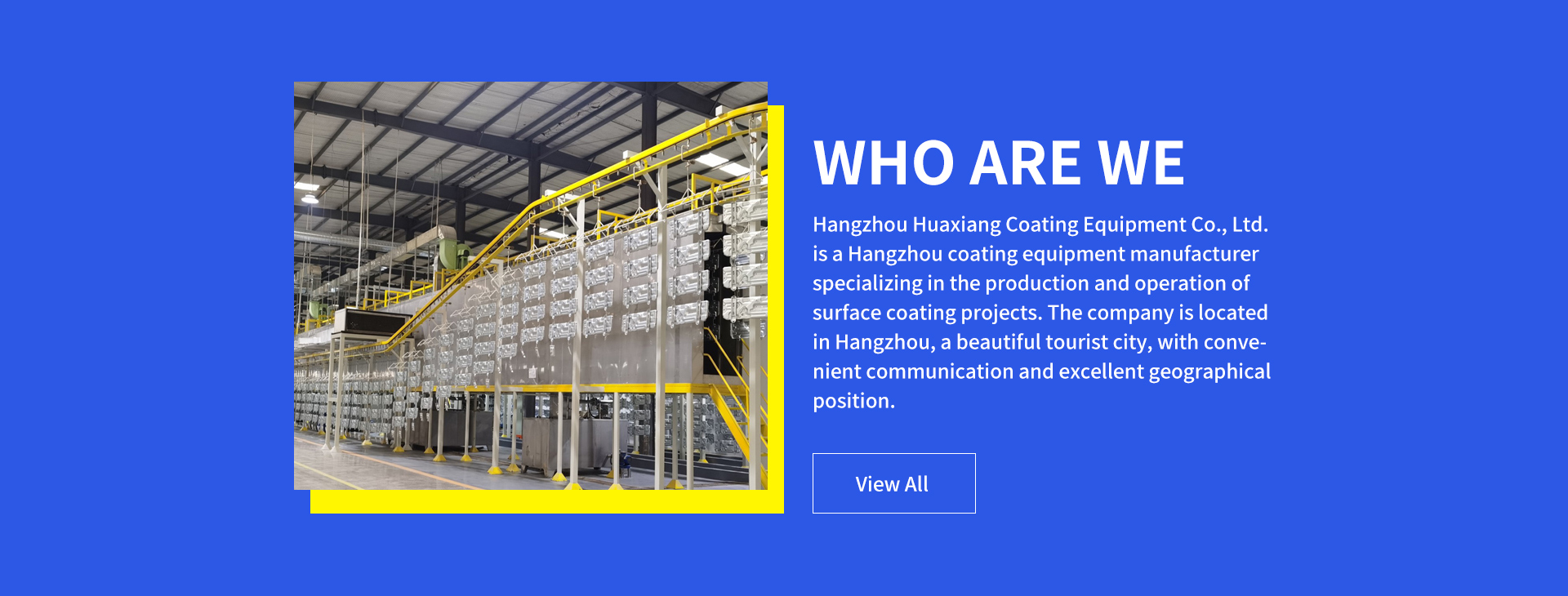

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com